The Development Process

At OCTOTRONIX, we've refined our development process to ensure that every project transitions smoothly from an initial concept through to manufacturing and rigorous testing, culminating in a market-ready product that exceeds expectations. Here's a detailed overview of each phase in our comprehensive development process

1 - Initial Brainstorming

The journey begins with your vision. During the discovery phase, we engage in in-depth discussions to understand your goals, target market, and the challenges we aim to solve. This collaborative ideation session helps in sketching a preliminary concept that aligns with your objectives

2 - Feasibility Study

With the initial concept in hand, we conduct a thorough feasibility study, evaluating technical requirements, market viability, and potential constraints. This ensures that the envisioned product is not only technically achievable but also commercially viable

3 - Detailed Design

Leveraging advanced CAD tools and simulation software, our design team transforms the concept into detailed designs, encompassing both the hardware and software aspects of the project. This phase includes creating schematics for electronic circuits, developing PCB layouts, and drafting detailed 3D models for mechanical component

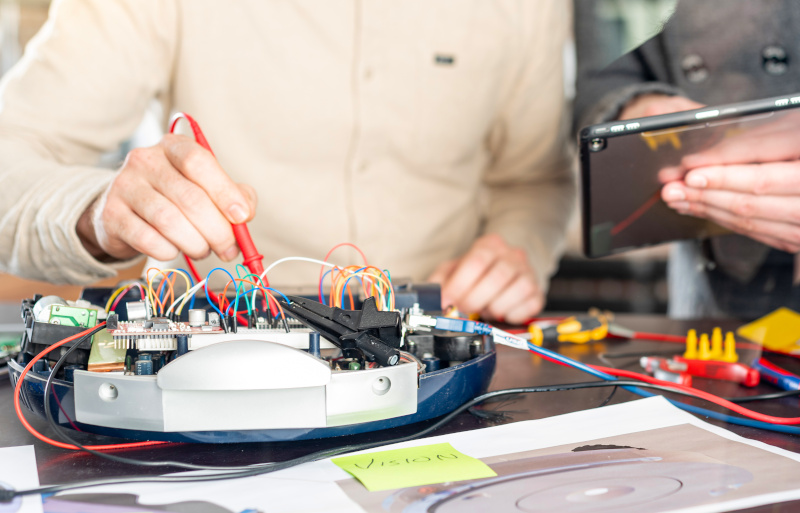

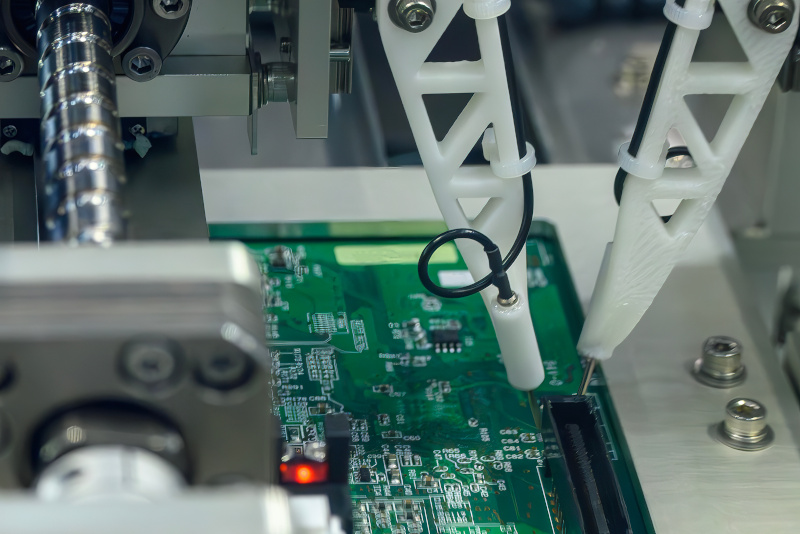

4 - Prototype Development

Leveraging advanced CAD tools and simulation software, our design team transforms the concept into detailed designs, encompassing both the hardware and software aspects of the project. This phase includes creating schematics for electronic circuits, developing PCB layouts, and drafting detailed 3D models for mechanical component

4 - Initial Testing

Each prototype undergoes a series of stringent tests to assess functionality, performance, and durability. This initial testing phase is critical for identifying any issues or areas for improvement.

5 - Iterative Refinement

Based on testing feedback, the design may be revised and refined. This iterative process of testing and refinement continues until the prototype meets all specified requirements and standards, ensuring that the final product will perform reliably in the field.

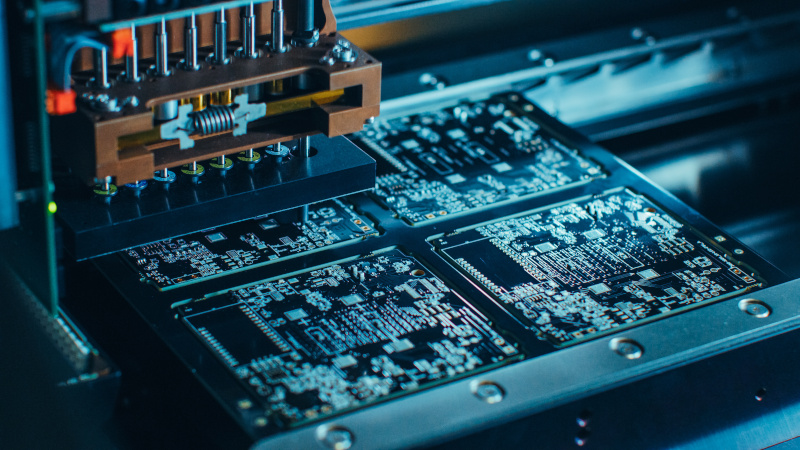

6 - Design for Manufacturability (DFM)

Before moving into mass production, we optimize the product design for manufacturability. This involves modifying the design to ensure it can be efficiently and cost-effectively manufactured at scale, without compromising quality or performance.

7 - Supplier and Materials Sourcing

Concurrently, we begin sourcing the necessary materials and components, leveraging our extensive network of suppliers to ensure the best quality and value. This phase also includes selecting manufacturing partners for both the electronic and mechanical parts of the project.

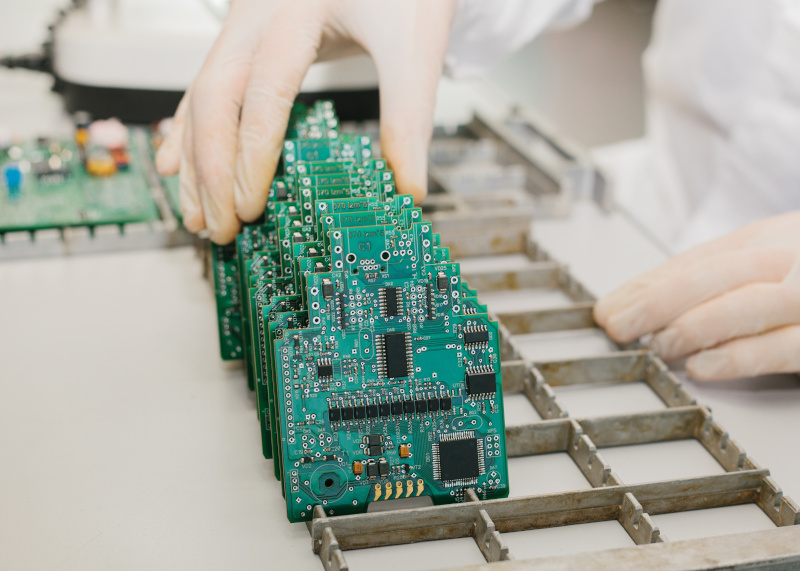

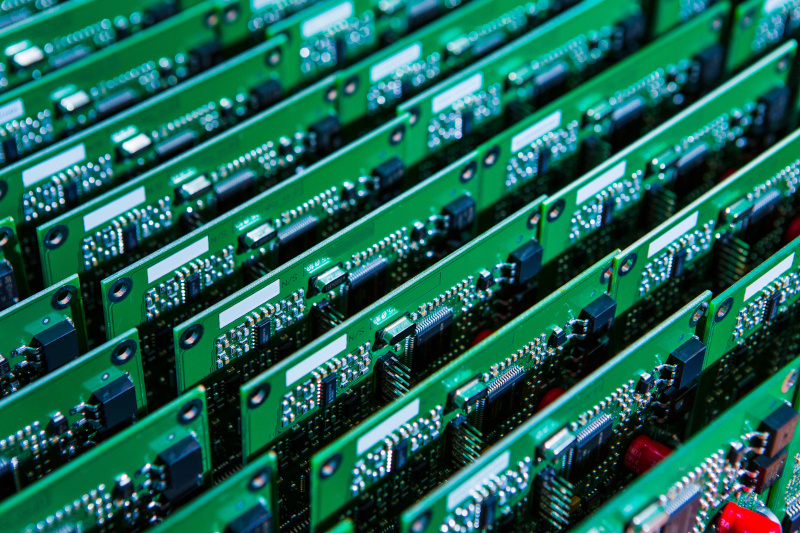

9 - Full-Scale Production

Once any adjustments have been made and quality is assured, full-scale production commences. Throughout this phase, we maintain strict quality control and oversight to ensure that every unit produced meets our high standards.

10 - Comprehensive Quality Testing

In parallel with manufacturing, we conduct comprehensive testing on production units. This includes functional testing, reliability testing, and compliance testing to ensure that the product adheres to all relevant standards and regulations.

11 - Final Quality Assurance

Before any product is shipped, it undergoes a final quality assurance check. This last review ensures that every product delivered to our clients or end-users meets the rigorous quality standards set by OCTOTRONIX.

Ready to Partner?

Fill the contact form so we can contact you as soon as possible.